Understanding Watch Jewels: Why Mechanical Movements Need Them

60-Second Summary

Watch jewels are synthetic rubies or sapphires strategically placed within mechanical movements to serve as bearings that minimize friction reduction between moving parts. These tiny gemstones, typically numbering 17-25 in standard timepieces, are positioned at pivot points where metal components would otherwise create excessive wear. The hardness of these jewel bearings (rating 9 on the Mohs scale) ensures smooth operation, enhanced accuracy, and extended movement longevity. From gear trains to escape wheels, watch jewels protect critical components while maintaining lubricant effectiveness. Understanding their role helps appreciate why quality mechanical movements rely on these precision-engineered bearings for optimal performance and durability.

What Are Watch Jewels and Why Do Mechanical Movements Need Them

Watch jewels represent one of the most ingenious solutions in horological engineering. When you examine a mechanical movement, you'll notice tiny red or clear stones positioned at specific locations throughout the mechanism. These aren't decorative elements but functional bearings that solve a fundamental problem in watchmaking.

Mechanical movements contain dozens of metal components that must work together with incredible precision. Without proper bearings, these parts would grind against each other, creating heat, wear particles, and ultimately destroying the movement's accuracy. Watch jewels eliminate this problem by providing ultra-smooth contact surfaces that dramatically improve friction reduction.

The Science Behind Watch Jewels as Bearings

Modern watch jewels are typically made from synthetic corundum (aluminum oxide), the same material used to create synthetic rubies and sapphires. This material choice isn't accidental. With a hardness rating of 9 on the Mohs scale, these bearings are nearly as hard as diamonds, making them ideal for withstanding constant motion without wearing down.

The manufacturing process creates perfectly smooth, consistent surfaces that allow metal pivots to rotate with minimal resistance. This precision engineering ensures that each jewel bearing maintains its properties throughout the watch's operational life.

Learn more about precision engineering in our guide on the 5 most accurate watch movements ever made.

How Watch Jewels Achieve Superior Friction Reduction in Movements

Friction reduction stands as the primary function of watch jewels in any mechanical movement. When metal components rotate against other metal surfaces, friction generates heat and microscopic wear particles that contaminate lubricants and damage precision surfaces.

Watch jewels solve this challenge through their exceptional surface properties. The polished jewel surfaces create almost frictionless contact points, allowing pivots to rotate smoothly with minimal energy loss. This efficiency translates directly into improved timekeeping accuracy and reduced wear on surrounding components.

Critical Locations for Jewel Bearings

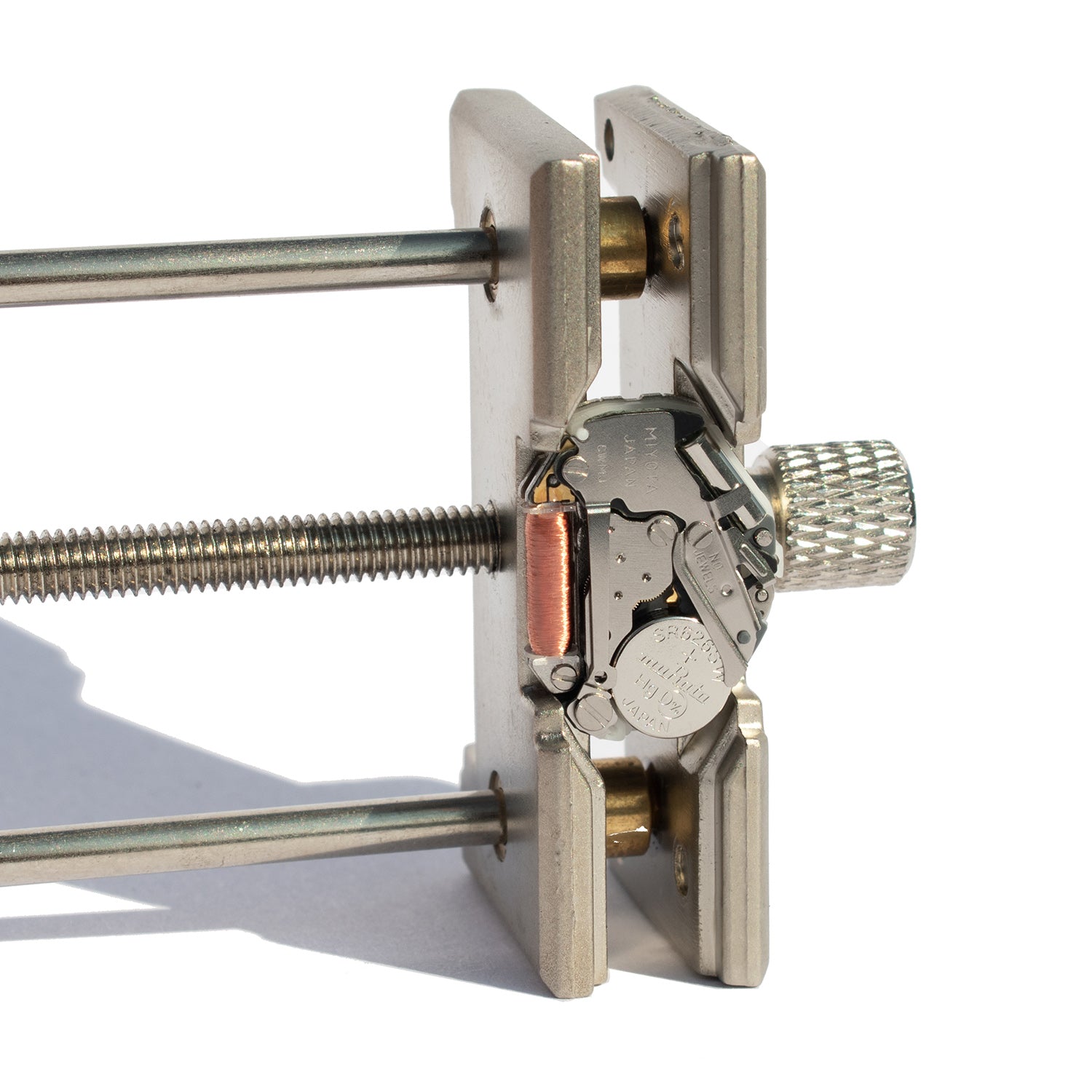

Mechanical movements place watch jewels at specific high-stress locations where friction reduction provides maximum benefit. The mainspring barrel requires jewel bearings to handle the constant tension from the wound spring. Gear train pivots use watch jewels to ensure smooth power transmission from the mainspring to the escapement.

The escapement mechanism, particularly the pallet fork and escape wheel, depends on jewel bearings for precise timing control. Without proper friction reduction at these points, the entire movement's accuracy would suffer dramatically.

For hands-on experience with these precision components, explore our Seiko NH36 Movement Kit which features 24 jewels strategically positioned throughout the mechanism.

Why Mechanical Movement Longevity Depends on Quality Bearings

Movement longevity directly correlates with the quality and placement of watch jewels throughout the mechanism. These bearings protect expensive movement components from premature wear while maintaining consistent performance over decades of operation.

Quality watch jewels resist degradation even under constant use. Unlike metal bearings that gradually wear down and create loose tolerances, jewel bearings maintain their dimensions and surface finish throughout the movement's life. This stability ensures that timing accuracy remains consistent year after year.

Protection Against Wear and Contamination

Watch jewels also protect mechanical movements from contamination damage. When metal components wear against each other, they create microscopic particles that mix with lubricants, forming an abrasive paste that accelerates wear throughout the movement.

Jewel bearings eliminate this contamination source by providing wear-resistant surfaces that don't generate particles. This protection helps maintain lubricant effectiveness and prevents cascade failures that could damage multiple movement components.

Understanding these principles becomes practical when you work with movements directly. Our movement kit selection helps you choose the right jewel configuration for your project.

Different Types of Watch Jewels and Their Specific Functions

Not all watch jewels serve identical functions within mechanical movements. Different bearing designs optimize friction reduction for specific applications and stress levels throughout the mechanism.

Hole jewels form the most common type, providing circular bearings for rotating shafts and pivots. These watch jewels support the majority of gear train components and handle radial loads from rotating elements. Cap jewels work in conjunction with hole jewels to provide thrust bearing capability, preventing axial movement of critical components.

Specialized Jewel Applications

Impulse jewels serve unique functions in escapement mechanisms, transferring energy from the escape wheel to the balance wheel. These watch jewels must withstand impact forces while maintaining precise timing relationships.

Roller jewels attach to balance wheels and interact with pallet forks to control escapement timing. The quality and positioning of these bearings directly affects chronometric performance and movement longevity.

For deeper insights into movement construction, check our comprehensive guide on Japanese watch movements.

How Many Jewels Your Mechanical Movement Actually Needs

The jewel count in mechanical movements varies based on complexity and intended function. Basic time-only movements typically use 17 jewels, providing bearings for essential components without unnecessary complexity or cost.

More sophisticated mechanical movements may contain 21-25 jewels, adding bearings for additional functions like date mechanisms or improved shock protection. Complications like chronographs or annual calendars can push jewel counts much higher, sometimes exceeding 50 watch jewels in complex pieces.

Understanding Jewel Count Marketing

Some manufacturers inflate jewel counts using non-functional watch jewels as marketing tools. True horological benefit comes from proper placement of bearings at high-stress locations, not from maximizing total jewel count.

Quality movements focus on strategic jewel placement for optimal friction reduction and movement longevity rather than impressive numbers. When evaluating movements, consider jewel placement and function rather than simple totals.

Practical experience with different jewel configurations helps build this understanding. Our Mega Movement Kit Bundle includes three different movements with varying jewel counts for comparison.

Maintaining Watch Jewels for Optimal Bearing Performance

Watch jewels require minimal maintenance when properly installed and lubricated. However, understanding their care requirements helps maximize movement longevity and performance consistency.

Proper lubrication keeps jewel bearings operating smoothly while preventing contamination buildup. Different lubricants serve specific functions, with lighter oils for high-speed components and heavier greases for shock-resistant applications.

Signs of Jewel Bearing Problems

Worn or damaged watch jewels create specific symptoms in mechanical movements. Increased positional variation indicates loose tolerances from worn bearings. Rapid lubricant degradation suggests contamination from damaged jewel surfaces.

Regular observation during normal use helps identify bearing issues before they cause extensive damage. Professional attention becomes necessary when jewel replacement or resetting is required.

Building practical maintenance skills helps preserve movement performance. Our watchmaking basics guide covers essential care techniques for jeweled movements.

Time isn't just measured, it's built with your own hands. Start your watchmaking journey with Rotate Watches, where complete DIY kits transform curiosity into craftsmanship. Browse our collection to find your perfect match, from complete watch kits to intricate movement kits. Your watchmaking story begins with a single screw. Start building today.

FAQ

Q. What are watch jewels made of?

Watch jewels are typically made from synthetic corundum (aluminum oxide), the same material as synthetic rubies and sapphires. This extremely hard material provides excellent friction reduction and durability.

Q. How many jewels does a good mechanical watch need?

A quality mechanical movement typically requires 17-25 jewels for optimal performance. More jewels don't necessarily mean better quality; proper placement for friction reduction matters more than total count.

Q. Do watch jewels wear out over time?

Watch jewels rarely wear out due to their extreme hardness. However, improper lubrication or shock damage can affect their performance as bearings in mechanical movements.

Q. Why are watch jewels better than metal bearings?

Watch jewels provide superior friction reduction compared to metal bearings because of their hardness and smooth surface finish. This results in better movement longevity and accuracy.

Q. Can you see jewels in a watch movement?

Yes, watch jewels are visible as small red or clear stones throughout the mechanical movement. Many watches feature exhibition case backs specifically to showcase these precision bearings.

Q. Do more expensive watches have more jewels?

Not necessarily. Expensive watches focus on quality jewel placement and movement finishing rather than maximum jewel count. Proper bearing design matters more than total watch jewels quantity.

{ "@context": "https://schema.org", "@type": "FAQPage", "mainEntity": [ { "@type": "Question", "name": "What are watch jewels made of?", "acceptedAnswer": { "@type": "Answer", "text": "Watch jewels are typically made from synthetic corundum (aluminum oxide), the same material as synthetic rubies and sapphires. This extremely hard material provides excellent friction reduction and durability." } }, { "@type": "Question", "name": "How many jewels does a good mechanical watch need?", "acceptedAnswer": { "@type": "Answer", "text": "A quality mechanical movement typically requires 17-25 jewels for optimal performance. More jewels don't necessarily mean better quality; proper placement for friction reduction matters more than total count." } }, { "@type": "Question", "name": "Do watch jewels wear out over time?", "acceptedAnswer": { "@type": "Answer", "text": "Watch jewels rarely wear out due to their extreme hardness. However, improper lubrication or shock damage can affect their performance as bearings in mechanical movements." } }, { "@type": "Question", "name": "Why are watch jewels better than metal bearings?", "acceptedAnswer": { "@type": "Answer", "text": "Watch jewels provide superior friction reduction compared to metal bearings because of their hardness and smooth surface finish. This results in better movement longevity and accuracy." } }, { "@type": "Question", "name": "Can you see jewels in a watch movement?", "acceptedAnswer": { "@type": "Answer", "text": "Yes, watch jewels are visible as small red or clear stones throughout the mechanical movement. Many watches feature exhibition case backs specifically to showcase these precision bearings." } }, { "@type": "Question", "name": "Do more expensive watches have more jewels?", "acceptedAnswer": { "@type": "Answer", "text": "Not necessarily. Expensive watches focus on quality jewel placement and movement finishing rather than maximum jewel count. Proper bearing design matters more than total watch jewels quantity." } } ] }