Understanding the Watch Mainspring: The Powerhouse of Mechanical Watches

What Is a Watch Mainspring?

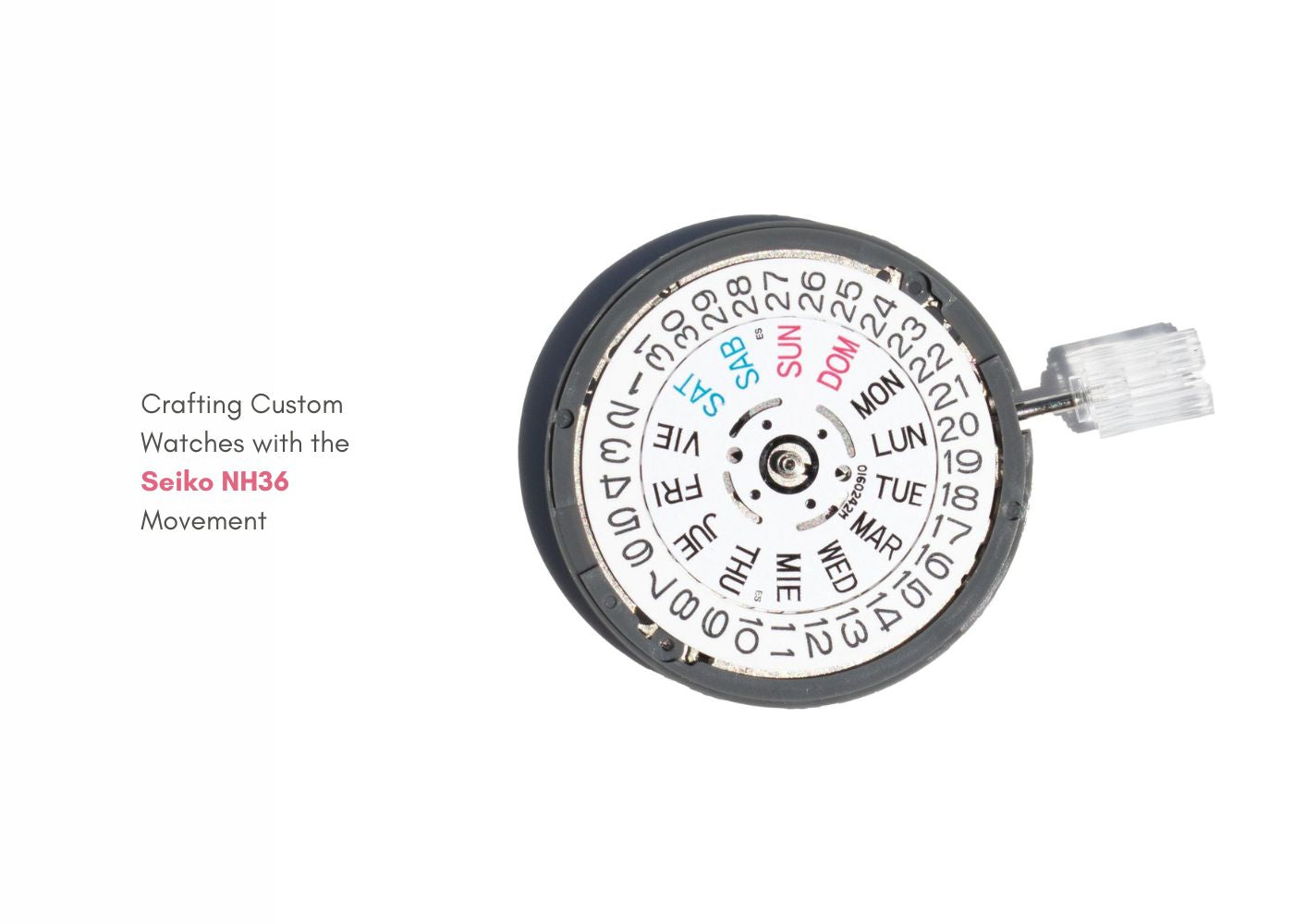

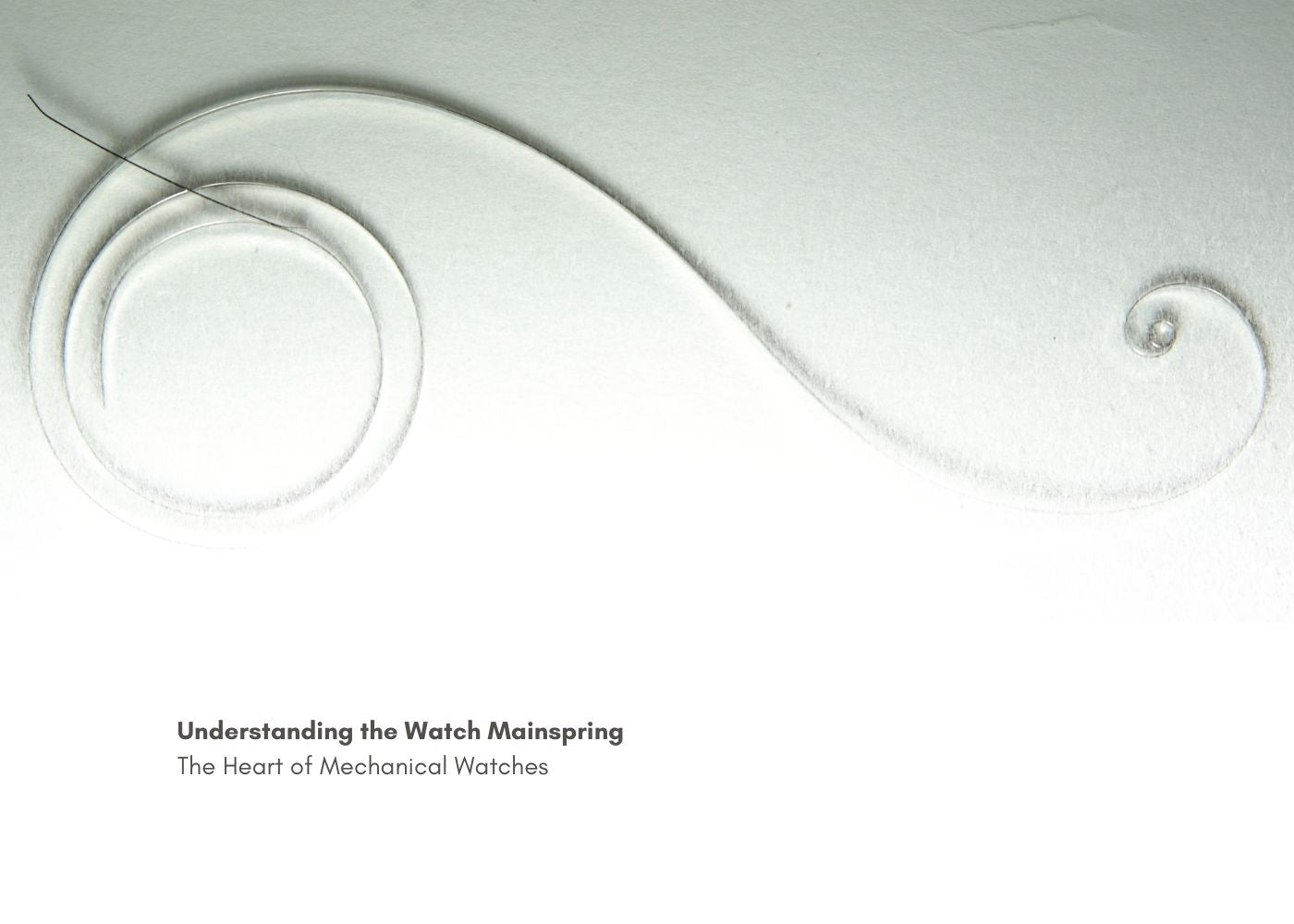

A watch mainspring is a spiral torsion spring made from metal ribbon-typically spring steel-that functions as the power source in mechanical watches and other clockwork mechanisms. This long, thin strip of hardened and blued steel (or specialized steel alloy) measures approximately 20-30 cm in length and 0.05-0.2 mm in thickness. When coiled tightly inside the watch's barrel, the mainspring stores potential energy that gradually releases to power the timepiece.

The mainspring concept dates back to the 15th century when mechanical watches transitioned from weight-driven mechanisms to spring-driven ones. This revolutionary change enabled the development of portable timekeeping devices, paving the way for the modern wristwatch.

How Does the Watch Mainspring Work?

The fundamental principle behind the mainspring remains elegantly simple despite centuries of refinement.

One end of the spring attaches to the barrel arbor (the central axle), while the other end connects to the barrel wall. When you wind your watch, either manually through the crown or via an automatic winding system, the spring coils tighten and store energy.

As the mainspring gradually unwinds, it releases this stored energy in a controlled manner, powering the watch's gear train-a series of wheels and pinions that transfer energy throughout the movement. The energy ultimately reaches the escapement, which regulates the release of power to ensure the watch ticks at a consistent rate, maintaining accurate timekeeping.

Ready to explore the fascinating world of mechanical watches firsthand? Rotate's Wright Watchmaking Kit offers everything you need to build your own mechanical timepiece and witness the mainspring in action.

Types of Watch Mainsprings

Mechanical watches generally use two types of mainsprings:

Traditional Mainsprings

Traditional mainsprings, found in manual-wind watches, feature a distinctive tongue at the end that fits into a hook in the barrel wall. This creates a definite endpoint when winding-you'll feel resistance when the spring reaches full tension.

The winding process starts easily but becomes progressively tighter until reaching this full-wind position, where the tongue/hook mechanism maintains maximum tension.

Traditional mainsprings are calculated to provide enough power for a watch to run approximately 36-40 hours, allowing for daily winding with a 12-16 hour power reserve in case the owner delays their winding routine.

Automatic Mainsprings

Automatic mainsprings differ significantly in their end design. Instead of a tongue, they feature a "sliding bridle" that pushes the mainspring tail against the barrel wall. The barrel itself contains multiple soft-sided cutouts and special grease around the perimeter rather than a hook.

Since the automatic winding mechanism never stops working (even when the watch is fully wound), these mainsprings need to prevent damage from overwinding. The sliding bridle allows the spring to slip once it reaches maximum tension, preventing binding or breakage while maintaining optimal power.

Experience both types of mainsprings with Rotate's Mega Movement Kit Bundle, which includes both hand-wound and automatic movements for comprehensive learning.

The Evolution of Mainspring Materials

The materials used in mainspring construction have evolved dramatically over centuries, with each advancement improving performance and reliability:

-

Early mainsprings were made from simple steel without tempering or hardening processes, requiring winding twice daily due to their limited power reserve.

-

Since 1945, traditional carbon steel has been increasingly replaced by specialized alloys containing iron, nickel, chromium, and additions of cobalt, molybdenum, or beryllium. These "white metal" springs offer superior elasticity, corrosion resistance, and magnetic immunity.

-

Modern proprietary alloys like Seiko's SPRON and Swatch Group's Nivarox represent the cutting edge of mainspring technology. These materials maintain consistent performance over thousands of winding cycles without developing the "tiredness" that plagued earlier springs.

-

Some contemporary manufacturers have even experimented with silicon and other advanced materials that eliminate the need for lubrication while maintaining ideal performance characteristics.

Manual vs. Automatic Mainsprings: Key Differences

The distinction between manual and automatic mainsprings extends beyond their physical design to their fundamental operation:

Power Delivery

Manual mainsprings typically deliver more consistent torque throughout their unwinding cycle, which can translate to more stable timekeeping. The direct winding mechanism allows for precise control over the spring's tension.

Automatic mainsprings must accommodate the variable winding provided by wrist movement, requiring more complex engineering to maintain consistent power delivery. Their sliding bridle design prevents overwinding while ensuring sufficient energy storage.

Power Reserve Considerations

The power reserve-how long a watch runs on a full wind-varies significantly between manual and automatic watches. Most mechanical watches offer 36-48 hours of power reserve, though some high-end models can run for days or even weeks on a single winding.

Manual watches generally require daily winding to maintain optimal performance, while automatic watches remain powered as long as they're worn regularly. However, if an automatic watch sits unworn for more than its power reserve period, it will stop and require manual winding or movement to restart.

Curious about building your own automatic watch? The Cabot Watchmaking Kit features a Japanese Seiko NH36 automatic movement with a generous 41+ hour power reserve.

The Importance of Mainspring Health

A watch mainspring's condition directly impacts overall performance and longevity. After decades of use, mainsprings in older timepieces may become "tired" or "set," deforming slightly and losing some of their force. This condition manifests as decreased running time between windings.

Signs of a tired mainspring include:

-

When relaxed in the barrel, more than 2 turns spiral loosely across the central space rather than pressing against the barrel wall

-

When removed from the barrel, the relaxed spring's diameter measures less than 2½ times the barrel diameter

Modern mainsprings made from advanced alloys resist this fatigue significantly better than their historical counterparts, but even the best springs eventually require replacement during comprehensive servicing.

Mainspring Mechanics in Different Watch Styles

Different watch styles utilize mainsprings in unique ways to achieve specific performance characteristics:

Dress Watches

Elegant dress watches like the Galileo Watchmaking Kit often employ thinner mainsprings to accommodate slimmer case profiles. Prioritizing aesthetical appeal over a strict focus on extended power reserves, with mainsprings calibrated for reliable daily performance.

Dive Watches

Robust dive watches demand exceptional reliability under challenging conditions. Their mainsprings must deliver consistent power despite temperature variations and physical shocks. The Marco Watchmaking Kit exemplifies this approach with its Seiko NH36 automatic movement, providing dependable performance for underwater adventures.

Chronographs

Chronograph watches with stopwatch functionality require mainsprings capable of powering both timekeeping and chronograph mechanisms simultaneously. These specialized mainsprings must deliver additional torque to drive the chronograph's complex systems without compromising accuracy.

Building Your Own Watch: Experiencing the Mainspring Firsthand

Nothing compares to the satisfaction of building your own mechanical watch and witnessing the mainspring's power in action. Rotate's watchmaking kits provide everything needed for this rewarding experience, from quality-checked components to comprehensive guides.

For those particularly interested in understanding movement mechanics, the Knight Watchmaking Kit offers a medium-difficulty build featuring a Seiko NH05 movement with an impressive 50-hour power reserve.

Conclusion

The mainspring remains the powerhouse of every mechanical watch, a testament to centuries of horological innovation. From its humble beginnings in 15th-century clocks to today's advanced alloy versions, this crucial component continues to power our fascination with mechanical timekeeping.

Whether you're a seasoned collector or just beginning your watchmaking journey, understanding the mainspring provides deeper appreciation for these remarkable machines.

Ready to experience the magic of mechanical watches firsthand? Explore Rotate's complete collection of watchmaking kits and discover the joy of building your own timepiece.

FAQ

Q. What is the mainspring of a mechanical watch?

The mainspring is a spiral torsion spring made of metal ribbon that stores energy when wound and gradually releases it to power the watch. It serves as the primary power source for all mechanical watches.

Q. What are the different types of mainsprings?

The two main types are traditional mainsprings (for manual-wind watches) with a tongue that hooks into the barrel wall, and automatic mainsprings with a sliding bridle that prevents overwinding in self-winding watches.

Q. What is the difference between automatic and manual mainspring?

Manual mainsprings have a definite endpoint when fully wound and deliver consistent torque. Automatic mainsprings feature a sliding mechanism that prevents overwinding while allowing continuous winding from the rotor's movement.

Q. How long does a typical mainspring last?

A well-maintained mainspring can last for decades. However, its lifespan depends on factors like usage, material quality, and environmental conditions.

Q. Can a damaged mainspring be repaired?

In most cases, a damaged mainspring needs to be replaced rather than repaired. Watchmakers typically replace the entire mainspring to ensure optimal performance and reliability.